Lean Operations Is About Reducing Two Forms of Waste

The following four methods can help you achieve your goals. Calculating and interpreting eps information wells fargo reports the following information in its 2015 form 10-k.

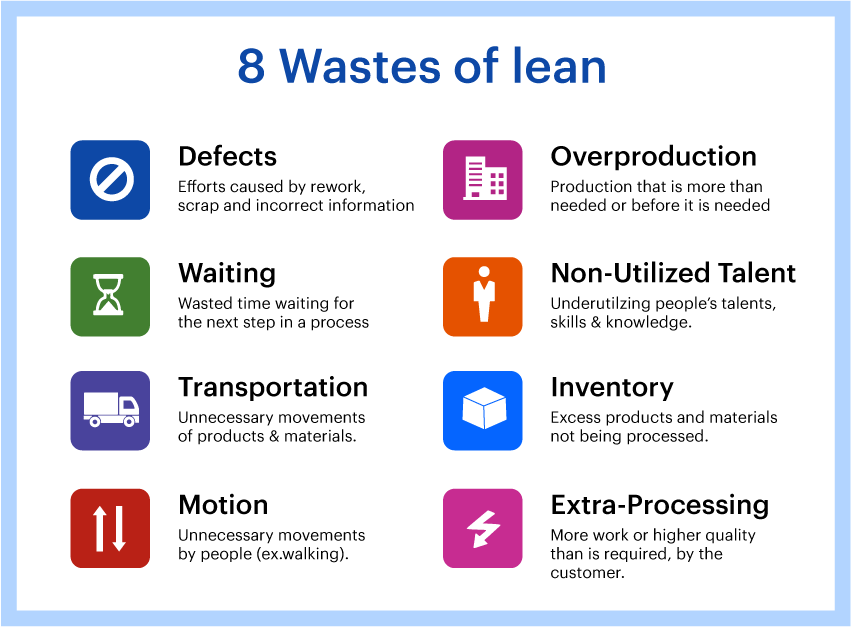

8 Wastes Downtime Using Lean Six Sigma Goleansixsigma Com

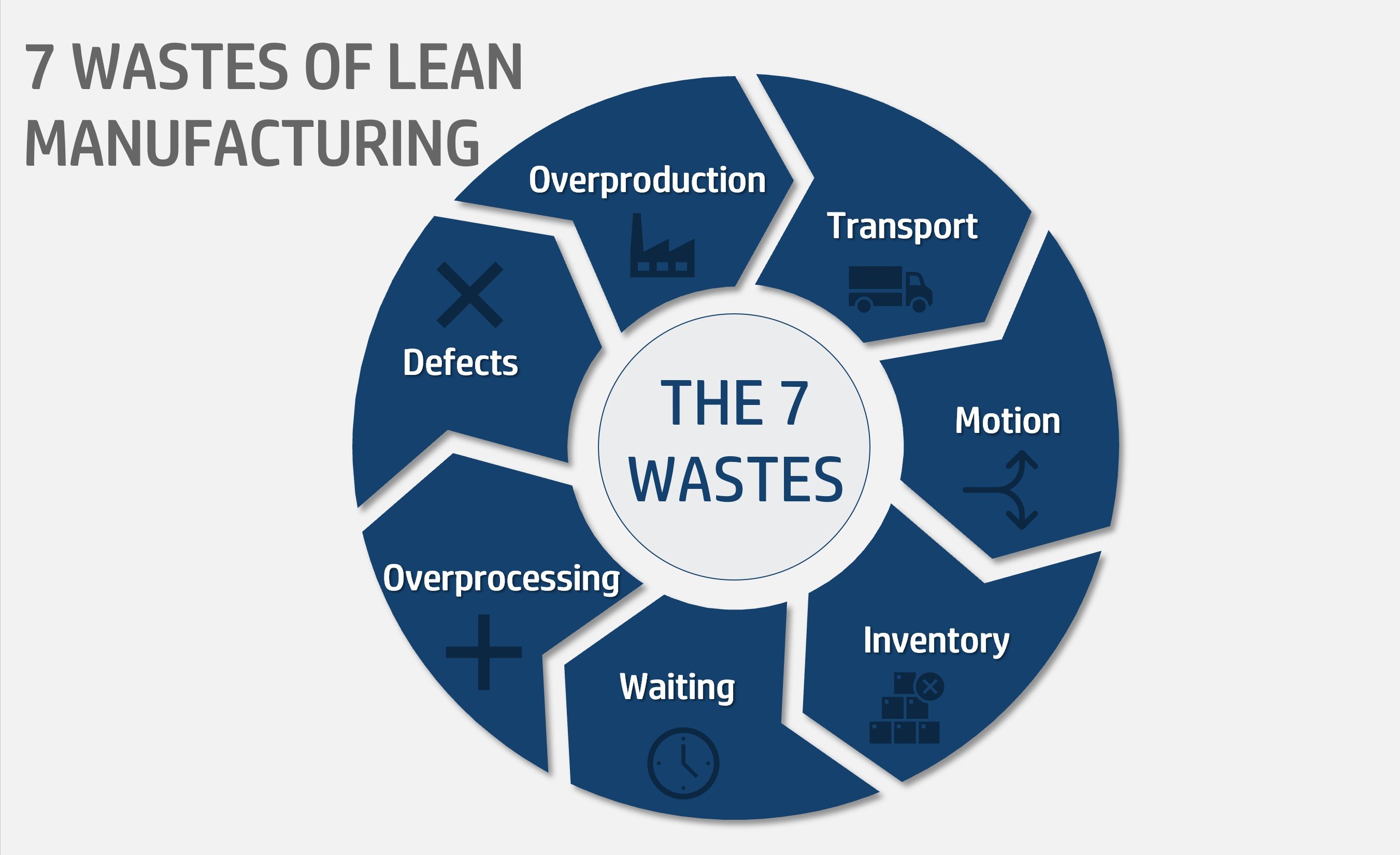

The essence of lean manufacturing is captured by the Five Lean Principles outer ring and the Seven Deadly Wastes.

. If you eliminate the cause of the waste first youll be building processes. It is also an effective way of reducing and managing existing waste within an enterprise. Transportation Reduce non-essential transportation in production by creating a U-shape production line or reducing the amount of work in progress.

Lean Concepts promotes the ideal of maximizing customer value while reducing waste. Increase customer value while reaching for a goal of zero waste. Although pioneered by Toyota in the mid-20 th century the principles and practices of lean manufacturing are widely applicable.

Work without value and overburden are straightforward enough but unevenness is essentially the absence of smoothness and flow in work processes. Before that can take place you have to reduce waste. Lean operations is about reducing two forms of waste wasted and wasted resource time flow unit time O inventory time O inventory capacity O inventory flow time.

Lean operation is a business strategy that stay on the concept of doing great with less. Lean Operations Definition Lean operations is a means of running an organization by focusing on providing greater customer satisfaction while using as few resources as possible. Decreasing or eliminating waste within your manufacturing operation is difficult but with lean methodology there are methods to to effectively conduct this process.

Companies that use lean operations are highly concerned with efficiency. Some scholars point out that waste of intellect ignoring the ideas of employees for problem solving and process improvement because of hierarchical concerns can very well be seen as an additional eighth source of waste. SORT get rid of the junk SET IN ORDER make products and equipment easy to find get and return SHINE keep up the cleanliness to show your employees and customers you care STANDARDIZE eliminate the guesswork around how to clean.

Reduce Excess Inventory and Overproduction. Waiting idle production time where processes are not optimally synchronized 5. With lean thinking an organization utilizes key processes to.

A costly process with a lot of waste can be streamlined but its still going to produce waste. T TF An operation is lean if. Motion - All movement of equipment not done in the easiest possible way 4.

To create lean business processes youll have to audit and reorganize them. The Lean theory describes 7 major areas where you can identify Muda activities more popular as the seven wastes of Lean. TF An example of a lean operation is to have workers standing around with mobile payment units waiting to check customers out.

Lean manufacturing is a way to strategically optimize and simplify the way an enterprise works and its environment. A production system that tries to reduce all types of waste at once is commonly called lean production. Lean operations is about reducing two forms of waste wasted and wasted.

View the full answer. Muda work that does not add value muri overburden and. Eliminating waste from the value chain has the highest priority in lean.

And the term waste doesnt refer. The LEAN 5S methodology can be applied to specific areas of your facility to minimize these forms of waste. Lean operations is about reducing two forms of waste wasted and wasted 9040 Multiple Choice O inventory capacity resource time flow unit time Inventory flow time o inventory time Prev 9 of 15 Next Help Save Exit Submit You received no credit for this question in.

The principles and techniques that make up lean are listed below. The objective of lean operations is twofold. For this topic we will explore the essence of lean from two perspectives.

Many businesses can benefit from adopting a lean manufacturing philosophy. Transportation Dont unnecessarily move products or materials 2. Value Stream Mapping VSM is a Lean management method for analyzing the current state and designing a future state.

The lean literature contains principles and techniques that can be used to reduce waste in organizations. At its core lean manufacturing is about maximizing customer value while minimizing waste. F TF A worker moving inventory from one machine to another is considered non-value-added work.

In millions 2015 2014. The traditional categories of waste in manufacturing processes. The concept argues there are eight primary wastes throughout business regardless of the industry.

The classic process for implementing lean. This type of waste is when you move resources materials and the movement doesnt add value to the product. The three main categories of waste in the Lean methodology are.

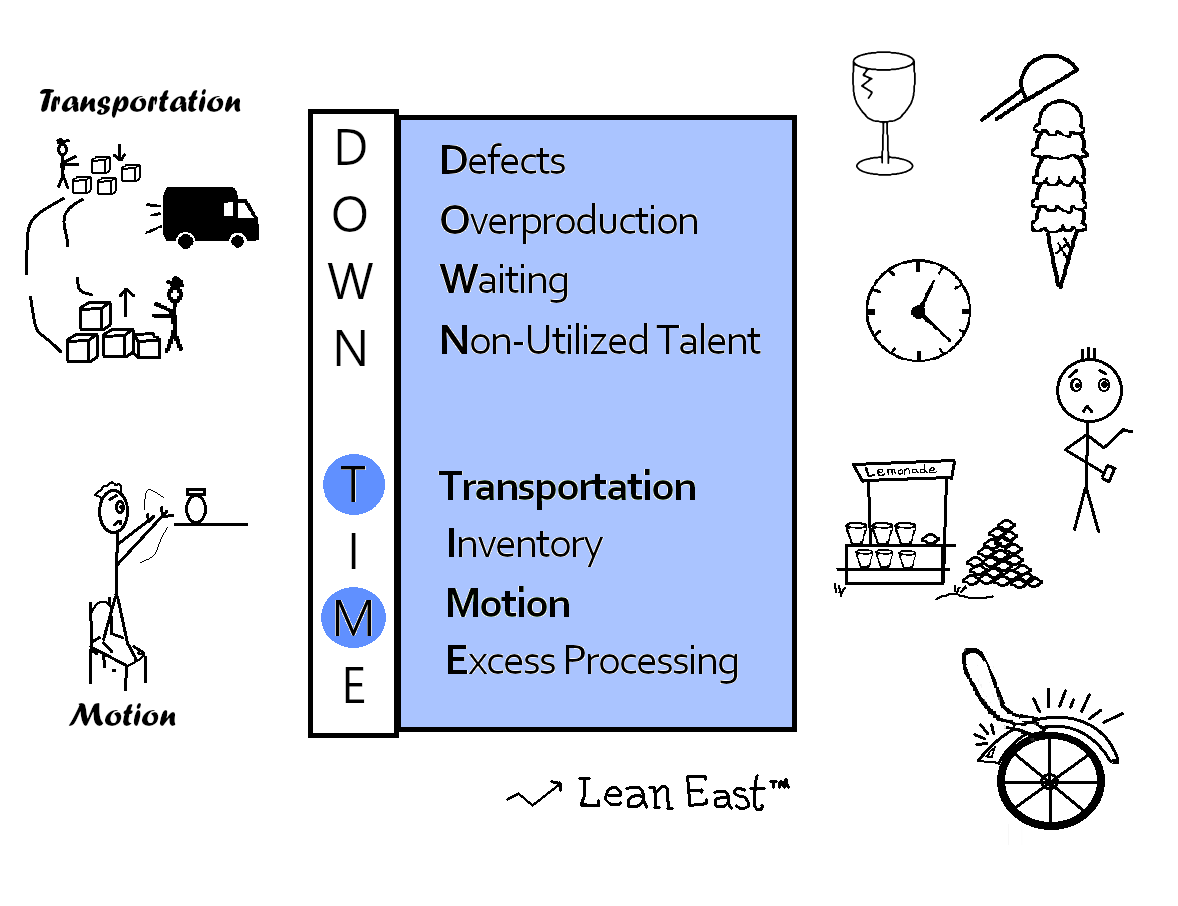

Inventory All the access products and material that are not being processed 3. Here the ultimate goal of lean operation is customer satisfaction. Some tips to reduce the TIMWOODS waste using Lean Six Sigma once it has been identified are.

What are the 7 wastes of lean. Creating value for customers and eliminating waste. Companies can also create different flows between processes.

But how can manufacturers effectively maximize lean manufacturing in order to reduce waste in their companies. The first step to reducing waste is recognizing that they exist and having an effective process for identifying them. Those processes must also be more effective and help you achieve your goals.

For example Nike was faced with negative public.

7 Reducing Waste In The Workplace Lean Office Lean Manufacturing Lean Six Sigma

8 Wastes Of Lean How To Identify And Eliminate Them

Essence Of Lean Eliminating Waste Muda Lean Production

Lean For Business Organizations 94 99 To Free Courses Learnfromhome Onlinelearning Udemy Coupon Udemy Business Organization

8 Wastes Of Lean Manufacturing Tulip

Essential Lean Management Presentation Diagrams Ppt Template With Principles Procedures And Kaizen 5s 5 Whys Tools Icons Writing A Business Plan Project Management Templates Principles

8 Wastes Of Lean Manufacturing Connected Worker Platform

8 Lean Wastes Transportation Vs Motion Lean East

Sensei Lean Lean Manufacturing Celdas De Manufactura Operations Management Lean Manufacturing Logistics Management

7 Types Of Waste In Lean Manufacturing

Operational Efficiency Ba 850 Sustainability Driven Innovation

7 Lean Wastes Overview Fastening Supply And Inventory Management Tr Falcon Fastenings

Seven Wastes 7 Mudas Of Lean Manufacturing

The 8 Wastes Of Lean Stop Wasting Your Resources

What Is A Non Value Added Activity When Customers Would Refuse To Pay For It Here Are 8 Examples Lean Manufacturing Types Of Waste Lean Office

8 Wastes Of Lean Manufacturing Techsolve

Comments

Post a Comment